What is a SCR System Fault: How Does SCR System Work

The Selective Catalytic Reduction (SCR) system is one of the most important systems in your vehicle because it reduces the emission of harmful pollutants, reduces engine friction, improves fuel economy, and boosts the overall power output.

However, just like any technology, SCR systems can encounter faults that hinder their performance. Your vehicle can face decreased engine power, increased exhaust emissions, warning codes and error codes as a result of the SCR system faults.

Let’s get into the details of the SCR system faults, and know the common symptoms. We’ll also underlie the causes, diagnostic methods, and preventive steps. Let’s explore how understanding and addressing these issues can help keep our vehicles running efficiently while staying environmentally conscious.

How Does An SCR System Work In Your Vehicle?

The Selective Catalytic Reduction (SCR) system is a technology used in diesel engines of vehicles to control emissions. Its purpose is to decrease the release of gasses, such as NOx in order to comply with regulations.

This system works by introducing a solution called diesel exhaust fluid (DEF) into the exhaust stream of a diesel engine. When DEF comes into contact with the nitrogen oxides (NOx) in the exhaust gasses it triggers a chemical reaction within the SCR catalyst.

Through this reaction, the NOx is converted into nitrogen and water vapor thus reducing the emission of pollutants into the atmosphere.

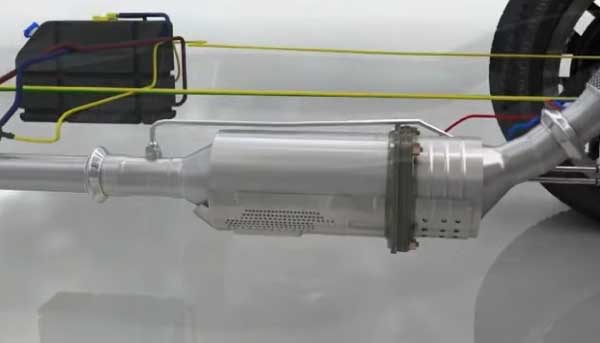

Key components of the SCR system include the DEF tank, which stores the nitrogen-based solution and injects it into the exhaust gasses before reaching the SCR catalyst.

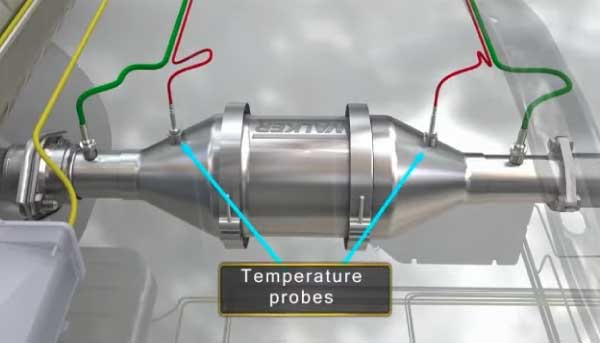

The SCR catalyst contains materials that facilitate and promote the reduction reaction of NOx. The injection of ammonia plays a role in initiating chemical reactions that break down NOx.

Common Symptoms of SCR System Faults

| Symptoms | Explanations | Examples |

| Decreased engine power or poor acceleration | A faulty SCR system can result in inadequate NOx reduction, leading to engine derating by the Engine Control Module (ECM). | A truck struggling to maintain speed on inclines due to decreased power output caused by SCR system malfunction. |

| Visible increase in exhaust smoke or darker exhaust emissions. | Incomplete NOx reduction due to a malfunctioning SCR catalyst can lead to higher levels of nitrogen oxides in the exhaust. | A car emitting thick, dark smoke from the tailpipe during acceleration, signalling excessive NOx emissions. |

| Abnormal DEF consumption rate, either too high or too low. | Incorrect DEF dosing due to sensor issues or system malfunctions can lead to irregular consumption patterns. | An increase in DEF consumption without a corresponding reduction in NOx levels, indicates a system malfunction. |

What Are The Causes of SCR System Faults? How to Solve Them?

Understanding the causes of SCR system faults is crucial for effective troubleshooting and maintenance. Here, we delve into the various causes of these faults and provide insights into how to address them.

SCR System Fault 1: Contaminated or Low-Quality DEF

- Cause: Using impure or low-quality Diesel Exhaust Fluid (DEF) can introduce contaminants or water, hampering the NOx reduction process.

- Solution: Ensure that you’re using DEF from reputable suppliers. Regularly inspect DEF storage conditions to prevent contamination. If contaminated DEF is suspected, drain the system, replace it with fresh DEF, and clean any affected components.

SCR System Fault 2: Sensor Malfunctions

- Cause: Faulty NOx sensors, temperature sensors, or pressure sensors can provide inaccurate data to the ECM, leading to improper DEF dosing.

- Solution: Conduct sensor diagnostics using suitable scan tools. Replace malfunctioning sensors with OEM-approved replacements. Clear error codes and recalibrate the system to ensure accurate sensor readings and proper dosing.

SCR System Fault 3: Exhaust Leaks or Damaged Components

- Cause: Leaks in the exhaust system, damaged SCR catalyst, or malfunctioning EGR components can disrupt exhaust flow and temperature, affecting SCR efficiency.

- Solution: Thoroughly inspect the exhaust system for leaks and damages. Repair or replace damaged components. Ensure proper installation and sealing. This will restore optimal exhaust conditions and maintain proper temperatures for SCR performance.

SCR System Fault 4: Electrical or Wiring Issues

- Cause: Damaged wiring, poor connections, or short circuits can disrupt sensor communication and ECM control, leading to inaccurate dosing.

- Solution: Inspect wiring and connections for damage. Repair or replace faulty wires and connectors. Ensure proper grounding. Conduct continuity tests to verify proper electrical flow. Re-establish proper connections to restore accurate data transmission and control.

SCR System Fault 5: Software Glitches and Calibration Problems

- Cause: Software bugs, glitches, or improper calibrations can lead to incorrect DEF dosing and compromised NOx reduction.

- Solution: Consult the manufacturer for software updates or patches. Perform ECM reprogramming as per manufacturer guidelines. Ensure the latest calibrations are applied to maintain accurate control of DEF dosing and NOx reduction.

Why Does the Vauxhall Mokka Service Light Need to be Reset?

The resetting vauxhall mokka service light is essential to maintain performance. It alerts you to upcoming maintenance needs, ensuring timely inspections and repairs. Ignoring it could lead to potential issues and negatively impact the car’s overall function. By resetting the service light, you are proactively maintaining your vehicle’s longevity and reliability.

How to Diagnose SCR System Faults?

Diagnosing SCR system faults is a systematic process that involves using various diagnostic methods to identify the underlying issues affecting the system’s performance. Here’s a step-by-step guide to effectively diagnose SCR system problems:

Step 1: Utilize Onboard Diagnostics (OBD) Codes

You can do it in two ways by checking the engine light of your vehicle. If the “Check Engine” light is illuminated, it often indicates an SCR-related issue. Use an OBD-II scanner to retrieve the specific error codes.

Step 2: Use Diagnostic Tools to Read Sensor Data

Connect an advanced diagnostic scan tool to the vehicle’s OBD-II port. After that, access the system’s data stream to monitor sensor readings related to NOx levels, DEF dosing, temperature, pressure, and other relevant parameters.

Now, observe how sensor readings change as the vehicle operates. Look for irregularities, fluctuations, or values outside the expected range.

Step 3: Analyze System Performance

Use the diagnostic tool to monitor the vehicle’s NOx reduction efficiency over different driving conditions. Compare the observed NOx reduction with expected values.

Step 4: Conduct Visual Inspections

Visually examine the exhaust system for signs of leaks, such as soot deposits, carbon buildup, or visible holes or cracks in the exhaust components. Then, inspect the SCR catalyst, DEF injectors, sensors, and wiring for physical damage or signs of wear.

Step 5: Interpret Diagnostic Information

Use the OBD codes obtained earlier to identify the specific component or system area triggering the fault. Also, analyze sensor data for any anomalies or inconsistencies that could point to a malfunctioning component.

Step 6: Pinpoint the Root Cause

Refer to your vehicle-specific diagrams or schematics to understand the flow of exhaust gasses, DEF, and electrical connections within the SCR system. Based on the gathered data, prioritize potential issues that could be causing the observed symptoms. Focus on the components or processes that are most likely to be responsible for the fault.

Step 7: Seek Professional Assistance

If the diagnosis process is complex or requires specialized tools, consult professional mechanics or technicians with expertise in SCR systems. Also, don’t hesitate to reach out to the vehicle manufacturer’s technical support for guidance on diagnosing and resolving challenging SCR system faults.

By systematically following these steps, you can diagnose SCR system faults with precision, identify the root causes, and take appropriate measures to restore the system’s functionality.

Additional Tips to Prevent the SCR System Faults

Maintaining optimal performance and preventing SCR system faults is essential for ensuring efficient emissions control and overall vehicle functionality. Below are some valuable tips to help prevent SCR system issues.

Choose High-Quality DEF

- Use DEF from reputable suppliers to ensure its purity and quality.

- Opt for DEF that meets ISO 22241 standards to guarantee proper chemical composition.

Monitor DEF levels regularly. Keep an eye on DEF levels and refill the tank as needed to avoid running out. It’s because running out of DEF can lead to system faults and reduced NOx reduction efficiency.

Also, be careful about the proper DEF storage.

- Store DEF in a cool, dry place away from direct sunlight.

- Avoid contamination by keeping DEF containers sealed and clean.

Inspect System Components

- Periodically visually inspect the SCR catalyst, DEF injectors, sensors, and wiring for any signs of damage or wear.

- Address any physical damage promptly to prevent further issues.

Regular Driving at Highway Speeds

- Regularly drive the vehicle at highway speeds for extended periods. This helps maintain proper exhaust temperatures and prevent potential catalyst clogging.

Keep the Exhaust System Clean

- Regularly inspect and maintain the exhaust system for leaks, damage, or corrosion.

- Clean exhaust components to prevent buildup that can affect exhaust flow.

Update Software

- Keep the ECM software up to date with the latest manufacturer-recommended updates.

- Updated software improves system performance and resolves potential glitches.

Apart from these tips, make sure you regularly clear the error codes. If error codes related to the SCR system appear, address them first and then clear them. Clearing error codes helps prevent false readings and enables accurate system diagnostics.

Conclusion

By now, you know that understanding and addressing SCR system faults is paramount. Through this guide, we’ve explored the common symptoms, causes, diagnosis methods, and preventive measures for SCR system issues. By staying vigilant, utilizing diagnostic tools, and practicing proactive maintenance, you can ensure your SCR system functions optimally, reducing emissions, maintaining performance, and contributing to a greener future.